< Previous week | Lecture and Studio Notes index | Next week >

Lecture 18: Reliability: Accidents Waiting to Happen

Lecture 19: Ownership and Sharing

Lecture 18: Reliability: Accidents Waiting to Happen

Not all engineers are pessimists but since good designs anticipate failure modes, many engineers must at least consider Murphy's Law (what can go wrong will go wrong) as they flesh out the details of their designs. Like Daedalus' wax wings flown too close to the sun, even designs that work well have limits and breaking points. If an engineered object is to work reliably, then the designers will have to carefully examine its multiple points of failure, including the three that today's challenges address: extreme forces, performance variations, and h.uman fallibility.

Challenge 1: Reliable Materials/use

Modified from a lesson described in:  Petroski, Henry. To Engineer Is Human: The Role of Failure in Successful Design. New York, NY: Vintage, 1992. ISBN: 9780679734161.

Petroski, Henry. To Engineer Is Human: The Role of Failure in Successful Design. New York, NY: Vintage, 1992. ISBN: 9780679734161.

Boxes of paper clips don't usually come with "a money back guarantee" since nearly everyone in the world who uses paperclips finds them a reliable way to hold a few pieces of paper together. But bend the paperclip wide a few times and it's likely to break. How many times will that be? We'll do a quick experiment to find out. Each of you will bend a paperclip back and forth until it breaks and we'll plot the data on a histogram.

Did all the paperclips break after the same number of bends? If so, why? If not, why not?

Reason 1:

Reason 2:

Mapping These Ideas to Your Project

This paperclip challenge spotlights two modes of system failure, namely

- fatigue of the materials that comprise the device and

- application of uncharacteristic forces.

As you've seen these affect each paperclip to differing degrees. When thinking about biotechnologies, what is akin to "material fatigue"? What situations might be considered uncharacteristic? How cell to cell differences can be taken into account is touched on in the next challenge but here let's apply material and use variations to the Eau dcoli project from the MIT 2006 iGEM team. Recall, these bacterial cells were designed to smell like bananas when they reach stationary phase.

- In your groups imagine at least two ways that the genetic material in this system might "fatigue" and how you'd know.

- Next define at least two environmental conditions that would derail the system and decide how likely these conditions are.

Challenge 2: Reliable Performance

The first challenge today addressed catastrophic failure--if breaking a paperclip can be called "catastrophic." The activity makes clear how engineers can enhance reliability by anticipating then obviating failure modes. Certainly, weaknesses can be tested and quantified, leading to reliability terms such as the "MTTF" (Mean Time To Failure). And certainly there are simple things to try that lengthen "MTTF" such as specifying operating conditions (“don't repeatedly bend the open clip back and forth") or including redundant functions ("use two paper clips when in doubt"). But catastrophic failure is only one way to fail. Today's second challenge will consider another mode of failure, namely unreliable performance.

The framework presented here is attributed to Reshma Shetty and the thesis work she did in the labs of Tom Knight and Drew Endy. She has developed a framework for characterizing transcription-based logic devices that we will modify to talk about system-level behavior.

To introduce digital devices and means for guiding reliable behavior, we'll watch the BioBuilder animation "Genetic Digital Devices."

Digital vs Analog Logic

As our starting point we'll consider the simplest Boolean logic gate, the inverter or NOT gate. This gate has just one input. When that input has a logical value = 1 the output of the inverter is logical value = 0. And when the input value is = 0, the output is =1. The truth table and transfer curve for such a digital logic device is shown:

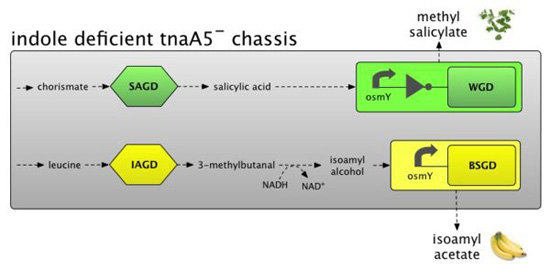

The inverter's transfer curve should remind you, just a little, of the shape of the curves we've already seen for the wintergreen and banana smell generators in the Eau d'coli project. Recall that the devices in this cell are controlled so that the wintergreen scent is generated only in log phase growth of the cell and the banana scent is generated only in stationary phase. The wintergreen scent, for instance, is programmed by a combination of a sensor (stationary phase promoter), a logic device (inverter), and an actuator (odor production). In fact if you examine the system level diagram that the team specified you'll see an inverter device regulating the conversion of salicylic acid to methyl salycilate.

Mapping the log-to-stationary phase concentration of methylsalycilate (in green) to the digital transfer curve (in red), you can see that activity of the green boxed wintergreen-generating device is swinging from a high value to a low value but the trip point (the input value at which the device inverts the output signal) is not precise. To impose digital logic on the analog signal, we'll have to impose thresholds. Thresholds designate a value above which the input for the device will be given a logic value = 1 and below which the logic value will = 0. You'll note that the thresholds still leave some values that have unspecified consequences for the operation of the device. You'll also note that the steeper the slope of the curve, the more accurately the gated signals will perform.

Please note that we have modified a framework that's useful for characterizing individual devices (e.g. sensors, logic devices, actuators) in order to describe the behavior of a system built with those devices. We've done this to help think about reliability in performance. Once your understanding of this description is solid for the system overall, it's worth thinking about the performance of each device that comprises the system and what the error rates might be for each.

See this Registry of Standard Biological Parts example of an input/output analysis for the stationary phase sensor itself and in combination with the inverter: Part:BBa_Q04401:Experience.

Performance Implications

In your group you should consider the following 3 questions:

- When thinking about biological analog to digital converters, what aspects of biology should be taken into account? (Note: you can restrict your thinking to systems that are controlled by transcriptional logic)

- What would be the consequence of a 10% error in the logic output for the wintergreen generating device? Would this be a tolerable error rate for this system?

- Would a 10% error rate be acceptable for a device in your own project? Why or why not?

Challenge 3: Reliable Sources

Here's a story that's been passed from teacher to teacher: two students spend the night before their big final exam at a party and they end up sleeping through the test. They tell the teacher that a flat tire is what kept them from the exam and the teacher, seemingly gullible, lets them retake the exam in separate rooms. The exam has only one question: which tire?

Very cute. Very clever. But is it true or urban myth? How do you know? Today you'll have a chance to sniff out fact from fiction with a scientific game of “I doubt it.” You'll hear three short stories from the scientific literature and you need to pick the fake one from the mix. This sniffing out of the truth will be harder than you might think. For one thing, these stories will be drawn from recent scientific developments and nature is incredibly imaginative. Consequently things that sound impossible turn out to be very real. In addition, there is often a personal set of beliefs that everyone works within, making stories that validate or reinforce those beliefs seem more plausible. One instance of such bias is the hoax article about climate change that many bloggers righteously touted as the truth revealed (Wikipedia page | PDF of hoax paper).

PS. The tire story turns out to be largely true as reported by the Chronicle of Higher Education. Many thanks to Duke Chemistry Prof. James Bonk for a great, mostly true story to tell.

Studio 10: Re-Design Day 1

Join the Registry!

Please designate one person from your team as the person to obtain an account at the Registry of Standard Biological Parts. You and your project team should identify a part that you'd like to spotlight from your project and then enter it into the Registry. See the details of this requirement in the Final Presentation guidelines.

Project Redesign Day

Today's session is devoted to working on your projects.

Lecture 19: Ownership and Sharing

This challenge was originally developed and written by Drew Endy.

Challenge: Inventor and Investor Role Playing

Many useful genetic parts are currently protected by patents. For example, "uses of green fluorescent protein" are protected by United States Patent #5,491,084. At least 200 more recent patents protect additional uses of various fluorescent proteins. Patents are a legislated form of "intellectual property" by which inventors are granted a limited-time monopoly (~17 years) during which they can control access to the patented technology (e.g., by selling exclusive or non-exclusive licenses). In establishing the U.S. patent system, the founders of our country wanted to balance the sharing of inventions (e.g., via the publishing of patent applications) while also encouraging the investment and profit needed to drive innovation.

For today's challenge, you will act as either the inventors and patent holders of various genetic parts or the investors hoping to assemble and earn $ off a completed system.

If you are an Inventor

- Each inventor holds a patent or two that cost either $1, $2 or $5 to secure. You will have to "pay" this money up front and will be reimbursed at the end of the day, either by the investor who will want to license your technology or by the clients/teachers.

- Patent holders may license the use of their patents for profit (exclusively or non-exclusively), or give away the rights for free

- Patent holders will not know how much the final client/teachers are willing to pay for the complete Eau d'coli system

- Be aware that there are 12 components needed to produce a full Eau d'coli system, namely:

- A genetically encoded "inverter"

- A "constitutive promoter"

- A "stationary phase promoter"

- A "transcription terminator"

- A "weak ribosome binding site"

- A "strong ribosome binding site"

- The gene encoding the "ATF1" enzyme

- The gene encoding the "BSMT" enzyme

- The gene encoding the "PCHA" enzyme

- The gene encoding the "PCHB" enzyme

- The gene encoding the "BAT2" enzyme

- The gene encoding the "THI3" enzyme

If you are an Investor

- Each investor is seeking to license the complete set of genetic parts needed to encode the Eau d'coli system.

- The first investor who is able to acquire licenses for all the genetic parts needed to encode the full Eau d'coli system will earn real cash money!! The pay out will be told to the investor group but should not be shared with the inventors and patent holders.

- The winning investor (if any) will be required to pay all inventors whatever fees might have been negotiated in obtaining the rights to use various genetic parts.

- If the promised fees are less than the pay out then the investor can keep any additional cash (really).

- If the promised fees are greater than the pay out then the investor must pay all additional licensing fees out of their own cash reserves. (really, but it would be better to re-negotiate your licensing deals than to have this challenge cost you $$).

Good luck and, perhaps, great profits!

|

Why are we doing this?? After the challenge, we'll consider the following questions:

|

< Previous week | Lecture and Studio Notes index | Next week >